Recommended Products

- YXL Series IE2 High Efficiency Aluminum Three Phase Induction Motors

- * Frame sizes:63 to 160

* Rated output: 0.12 to 18.5kW

* Voltage: 380V

* Frequency: 50Hz or 60Hz

* Number of poles: 2, 4, 6, 8

* Efficiency levels: IE2

* Duty Cycle: S1

* Enclosure: IC411 – TEFC

* Insulation class: F

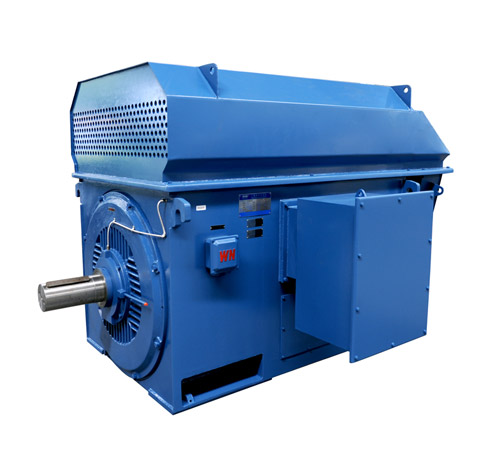

* Degree of protection: IP55- YKK Series High Voltage Three Phase Induction Motors

- * Frame sizes: 355-1000 * Rated output: 185-8000kW * Insulation class: F * Degree of protection: IP54 /IP55 * Enclosure: IC611 * Mounting: Horizontal * Rotor: Squirrel cage * Bearing: Rolling bearing or sleeve bearing * Voltage: 6kV, 10kV * Efficiency: IE1 & IE2 & IE3

- Z4 Series DC Motors

- * Frame sizes: 100-450 * Rated output: 1.5-600kW * Insulation class: F * Voltage:160V / 440V * Duty cycle: S1 * Excitation mode: Separate excitation * Rotation speed: 3000,1500,1000,750,600,500,400,300,200r/min

- NS series Premium Efficient Stainless Steel Motors

- * Frame:56C~286TC * Out Power:0.25HP~30HP * Inverter Duty Rated: 3:1CT & 5:1VT * Service Factor: 1.15 * Design: "B" or “C” * Protection Degree: IP55 * Enclosure: TEFC * Efficiency:Premium Efficient

- Y2 Series Medium size Three phase Induction Motors

- * Frame sizes: 355-560 * Rated output: 185-1600kW * Insulation class: F * Degree of protection: IP54 * Enclosure: IC411 * Rotor: Squirrel cage * Voltage: 6Kv, 10Kv * Mounting: Horizontal

- YLKK series medium size Vertical Type three-phase asynchronous motors (H355-630)

- * Frame sizes: 355-630 * Rated output: 185-2240kW * Insulation class: F * Enclosure: IC611 * Degree of protection: IP44/IP54 /IP55 * Rotor: Squirrel cage * Mounting: Vertical * Voltage: 6kV, 10kV * Efficiency level: IE1 & IE2 & IE3

- YXEJ Series High efficiency AC Squirrel cage brake motors

- * Frame sizes: 80 to 315 * Rated output: 0.18 to 200kW * Voltage: 380V * Frequency: 50Hz * Efficiency levels: IE2 * Enclosure: IC411 – TEFC * Degree of protection: IP55 (motor) & IP23 (brake) * Braking mode: Power failure brake * Rectification code: Half wave rectification

- YLVF Series low-voltage high-power inverter three-phase asynchronous motor

- * Frame sizes: 400 to 450 * Rated output: 185 to 800kW * Insulation class: F * Voltage: 380V * Frequency range for 2P: (3) 5-60Hz (frame size 400-450) * Frequency range for 4, 6, 8, 10P: (3) 5-100Hz

Top articles

- We have received Provincial Honors

- ISO Certification Re-evaluation

- Anhui Province industrial boutiques

- China Top 500 Machinery

- National May Day Labor Medal

- Chinese New Year

- Top 100 Comprehensive Manufacturing Enterprises of Private Enterprises in Anhui Province in 2023

- IE4 efficiency Explosion-proof motor has successfully passed the national supervision and random inspection

- Welcome new people to join Wannan Motor

- Wannan Motor successfully participated in EASA Fair

Latest articles

- We have received Provincial Honors

- ISO Certification Re-evaluation

- Anhui Province industrial boutiques

- China Top 500 Machinery

- National May Day Labor Medal

- Chinese New Year

- Top 100 Comprehensive Manufacturing Enterprises of Private Enterprises in Anhui Province in 2023

- IE4 efficiency Explosion-proof motor has successfully passed the national supervision and random inspection

- Welcome new people to join Wannan Motor

- Wannan Motor successfully participated in EASA Fair

Your browsing history

The first successful of the cast aluminum technical transformation project

On January 13, 2023, all the test machines of the first phase of the casting aluminum technology transformation project in rotor workshop were completed, including 7 die casting machines, two of which were 63 tons, three were 100 tons, one was 160 tons and one was 200 tons.

The first phase of the cast aluminum technical transformation project started on July 28, 2022. Due to the impact of the epidemic, the construction period lasted for five and a half years from floor building to the completion of the trial machine. Project design high starting point, high standard, reasonable overall layout, advanced equipment and technology, the construction process has learned the previous experience, in addition to the new die casting machine, but also equipped with the shaft press, aluminum smelting furnace, graphite crucible, false shaft through the punching table, KBK flexible crane and smoke purification system and other necessary auxiliary equipment.

Next, we will, as always, focus on the second phase of project construction after the year, go all out to improve the automation level of casting aluminum, realize batch production and process upgrading, and ensure the smooth transition of rotor quality and capacity.

WNM Motor, Industrial Solutions.

Previous page:IE5 efficiency Flameproof MotorNext page: New Office Building

Keywords in the article: High efficiency motor Single phase motor NEMA standard motor Low voltage motor